승인시험(IREA)

IREA, Integrated Reliability Engineering & Audit

Why is it, IREA (Integrated Reliability Engineering & Audit)

Since failure events related to material/manufacturing/other design problems have occurred more than occasionally in some major process turbomachines after their warranty periods have passed, it may well be required to execute the Integrated Reliability Engineering & Audit (IREA, Including Comprehensive Design/Material/Manufacturing Engineering Review and Audit) Program, which is definitely more comprehensive and integrated and enhanced than the API Rotordynamic Design Audit.

Issues of IREA

- API Rotordynamic Design Audit

- Blade HCF Assessment and Material Reliability Investigation

- Manufacturing Quality Reviews

- - High-speed Balancing Test

- - Mechanical Running Test

- - Factory Acceptance Test (FAT) for Motors

High-Speed Hydrodynamic Journal/Thrust Bearing Retrofit Design and Manufacturing Supervising

API Rotordynamic Design Audit

What is API Rotordynamics Design Audit and

why is it needed?

- From statistics, more than 50% of malfunctions and failures in newly acquired turbomachines are attributed to manufactures' (vendors') faults, related to design/material/ manufacturing (design: over 20 %, manufacturing/material: 12 - 18%)

- If specifying and managing a mechanical acceptance test only without also requiring a design analysis and review prior to construction, may result in:

- The discovery of design-related problems during shop tests that will likely compromise the planned cost of the unit and/or its delivery schedule.

- Especially, forcing a purchaser to accept an equipment that will prove problematic later after installation.

- Acknowledging the importance of rotordynamics design analysis for a proposed or premanufactured design and reflecting the sophisticated rotordynamics computer-analysis tools developed over the past 30 years, the latest API Standards specify the following threephase rotordynamics (reliability) acceptance program:

- Modeling and analysis of the proposed or premanufactured design.

- Evaluation of the proposed design, according to offered acceptance/rejection criteria.

- Shop testing and evaluation of the assembled machine, according to offered acceptance/ rejection criteria.

- As the latest API three-phase rotordynamics acceptance program has been faithfully implemented by turbomachine vendors, the discovery of design-related vibration problems during unit tests has decreased substantially.

API Rotordynamic Design Audit

- In particular, as many new projects of energy.refinery. petrochemical gas plants, which well exceed the vendors' proper management capacities of design and construction, are on-going worldwide, the well-organized independent API Rotordynamic Design Audit programs by purchasers (or users' own) shall need to be implemented.

- Besides, no manufacturer would give you any machine related information, something valuable for later maintenance and trouble-shooting unless you ask at early start of project. Therefore, at the beginning of project, a user needs to clearly specify what kinds of design and maintenance related information and reports he or she wants to have, according to API 617/612/616/684 or any eligible international standards

- Issues of API Rotordynamic Design Audit of Compressors & Turbines:

- Lateral Vibration - API 617 Stability

- Level I/ || - Torsional Vibration

- Blade HCF (High Cycle Fatigue) Assessment, etc.

- Total 3rd Party Audit Service

-

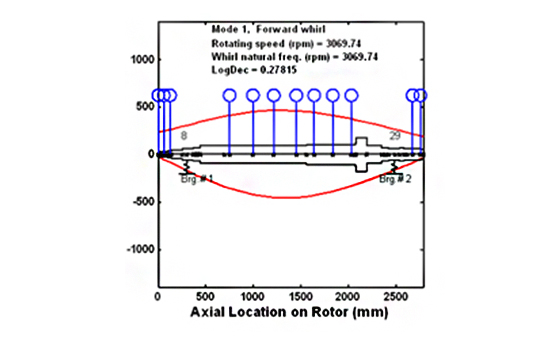

Typical damped mode analysis result of process multi-stage compressor rotor

Typical damped mode analysis result of process multi-stage compressor rotor

-

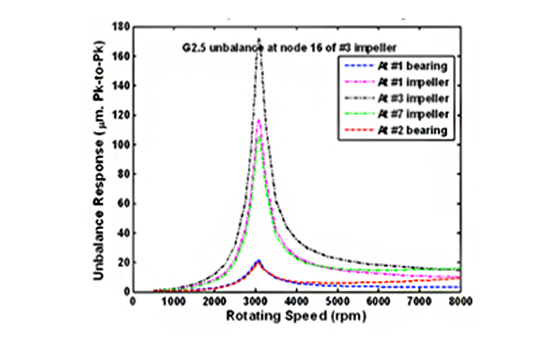

Typical unbalance response analysis result of process multi-stage compressor rotor

Typical unbalance response analysis result of process multi-stage compressor rotor

Bearing Retrofit Engineering and Design

- Once a machine has been designed and, especially, manufactured and installed in a site, it has often proved to be very difficult to fundamentally correct the machine's ailing design related problems. If this is the case, sometimes, the bearing retrofit can be only viable option, bringing about a successful result.

- Major Issues of Oil-Bearing Retrofit Engineering and Design:

- Vibration Reduction

- Stability Improvement

- Temperature, Load Capacity, and Minimum Film-Thickness Improvements, etc.

- Kinds of Retrofits

- Original fixed to better/optimized

fixed bearings - Original fixed to better/optimized

tilting pad bearings - Original tilting pad to better/optimized

tiling pad bearings

-

Typical damped mode analysis result of process multi-stage compressor rotor

Typical damped mode analysis result of process multi-stage compressor rotor

-

Typical unbalance response analysis result of process multi-stage compressor rotor

Typical unbalance response analysis result of process multi-stage compressor rotor

Blade Failure Investigation

- Some uncountable major reliability or availability risks of major turbomachines come from failures of blades whether their designs are centrifugal or axial type. In case of large process turbomachines, as a machine is usually made-to-order, depending on a user's varying specific process needs, a manufacturer may not have sufficient reliability references for its design, test and field operation.

- If a blade failure accident occurs, to stop the reoccurence a user should conduct his own investigation and review in parallel with a manufacture's investigation and report. Only when the user investigates and presents his or her own specific opinions, the manufacturer often tends to come to an one-step forward serious inspection in a duly reaction.

- Areas of Blade Failure Investigation and Service :

- Metallurgical Forensic Investigation

- Mechanical Investigation : Both of System and Blade Component Levels

- Applications : Axial Blades and Centrifugal Impeller Blades

-

Oxygen plant air compressor impeller-blade failure

Oxygen plant air compressor impeller-blade failure

-

FCC axial compressor blade failure

FCC axial compressor blade failure

Balancing Engineering and Review

- A single most predominant vibration source in any turbo or rotating machines is the rotor mass unbalance of any kinds. Depending on a specific machine type and design, the low-speed balancing only or high-speed balancing together must be implemented properly. An end-user should have some thorough understanding or knowledge of balancings and know how to review and judge a balancing report in right ways.

- Areas of Balancing Engineering and Review Service

- Specification of optimal balancing methods and procedures

- Low-Speed Balancing Quality Assessment

- High-Speed (or Operating-Speed) Balancing Quality Assessment

-

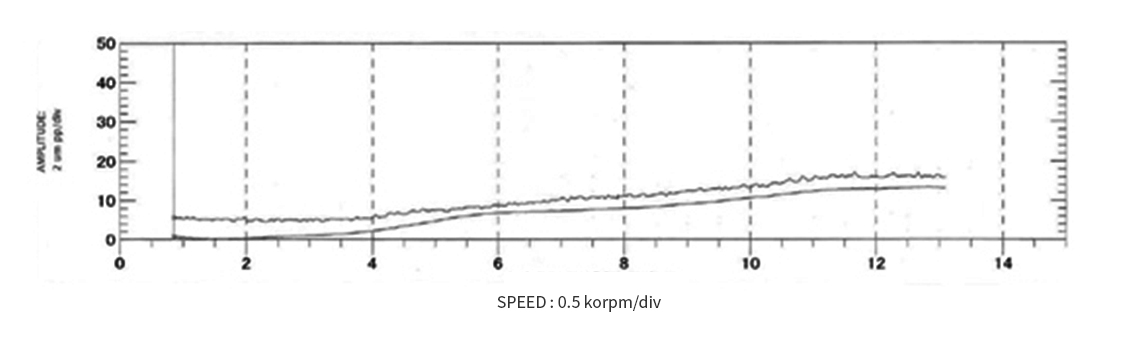

An example of questionable or later found-to-be problematic high-speed balancing result of gas-plant multi-stage compressor rotor, operating at 13,100 PP

An example of questionable or later found-to-be problematic high-speed balancing result of gas-plant multi-stage compressor rotor, operating at 13,100 PP

Motor Acceptance Test and Verification

- Presently, power drivers for large turbo-machines more frequently change from steam turbines to induction motors or high-speed direct motors. During on-site commissioning a commission-delay occurs quite often due to the motor-related troubles. By detecting defects and taking correctional's shop, potential commission-delays are preemptively eliminated.

- Areas of Motor Acceptance Test and Verification Service

- Electrical Acceptance Test

- Vibration Acceptance Test

- Mechanical Design Verification : Rotordynamics/Bearing Design

-

FAT test of 1000kW 2-pole motor

FAT test of 1000kW 2-pole motor